Types and Roles of Noise-Absorbing Sheets

There are various types of noise countermeasure sheets, each serving specific purposes:

– Absorption and suppression of radiated noise

(reducing noise emitted into surrounding space)

– Blocking interference between adjacent components

(preventing interference between high-frequency ICs and antennas)

– Reduction of conducted noise

(preventing noise propagation through power lines and enclosures)

These sheets are typically based on ferrite materials, magnetic compounds, or conductive materials, and must be selected according to frequency range, installation location, and application.

Sheet Form as the Default—A Mismatch with Mass Production

Most noise-absorbing materials on the market today are supplied only in sheet form.

However, this often leads to common complaints from manufacturing sites:

– “There’s no supplier who can process this into the required shape.”

– “Sheet materials can’t be used with automatic placement machines.”

– “We’re forced to apply them manually, which doesn’t scale for mass production.”

As a result, even effective countermeasure materials face cost, repeatability, and productivity barriers, preventing widespread adoption.

OTIS Processing Solutions: Bringing Noise Countermeasures into Mass Production

To address these challenges, OTIS provides the following solutions:

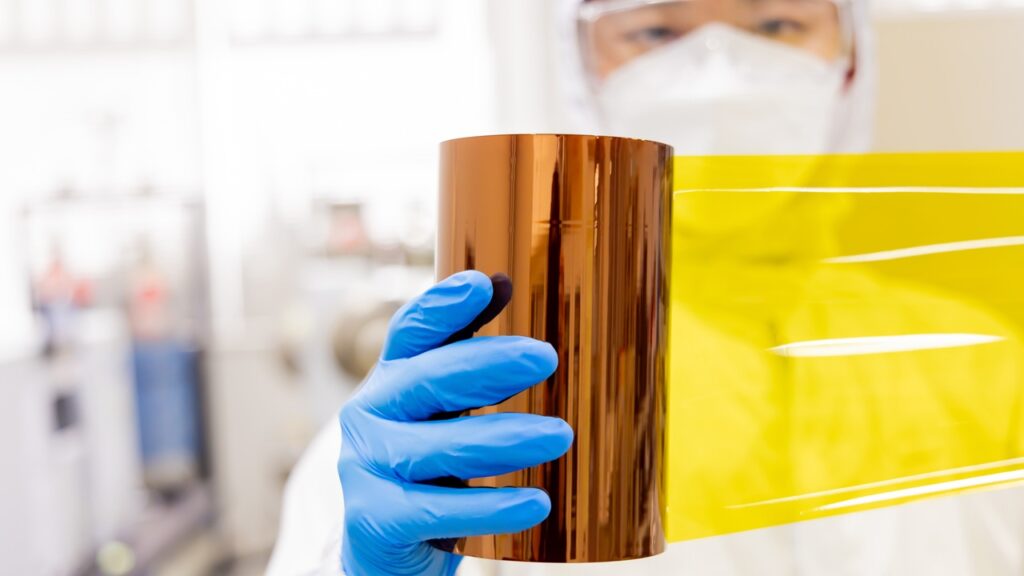

Conversion to Reel-to-Reel Processing

Even materials normally distributed only as sheets can be converted into continuous reel formats using our proprietary processing technology.

This enables seamless integration into automated production lines.

Shape Design Compatible with Automated Placement Equipment

We design shapes optimized for your mounting equipment, placement pitch, and component size—

taking into account positional accuracy, transport stability, and alignment tolerances.

This enables fully hands-free implementation.

Material-Manufacturer Agnostic

We support noise-absorbing sheets and conductive films from any manufacturer.

We also offer flexible processing of customer-supplied materials and custom specification adjustments.

Benefits for Material Manufacturers as Well

The biggest barrier to adopting sheet materials in mass production is often usability—specifically, shape and supply format.

By converting existing sheet materials into easy-to-use components, OTIS helps material manufacturers overcome challenges such as:

– “Our material can’t be adopted on the production floor.”

– “Manual application makes sales proposals less competitive.”

– “Selling sheets alone leads to pure price competition with little differentiation.”

Through reel-based specifications and mass-production-ready components, we help transform materials into value-added solutions.

Conclusion: From “Can Be Applied” to “Can Be Used”

Noise-absorbing sheets are often the last hope for protecting product reliability.

But to make that hope truly work on the production floor, processing, supply format, and implementation design must work together.

At OTIS, we act as the bridge between:

– Material manufacturers

– Production engineering and manufacturing teams

– Design departments

Supporting the mass production of noise countermeasure components in a way that benefits all three.

Start with a Technical Consultation

We welcome inquiries from material manufacturers as well as requests for customer-supplied material processing.

Koji Kakumoto

OTIS Corporation

After studying abroad for language training and gaining experience in planning and product development at a trading company, I joined OTIS Corporation in 2011.

I have worked primarily in corporate planning while also being involved in manufacturing and engineering operations. Since 2018, I have served as President and CEO, focusing on driving business growth and strengthening the organization.

This article is intended for educational and informational purposes only and does not refer to or endorse any specific company, product, or proprietary technology.