Why Is ±0.01 mm Precision Required?

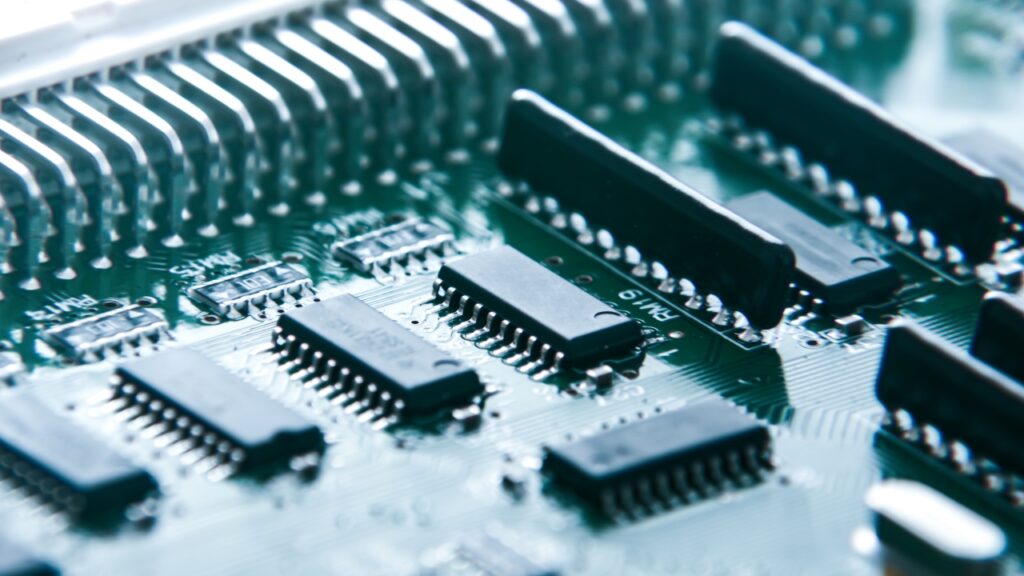

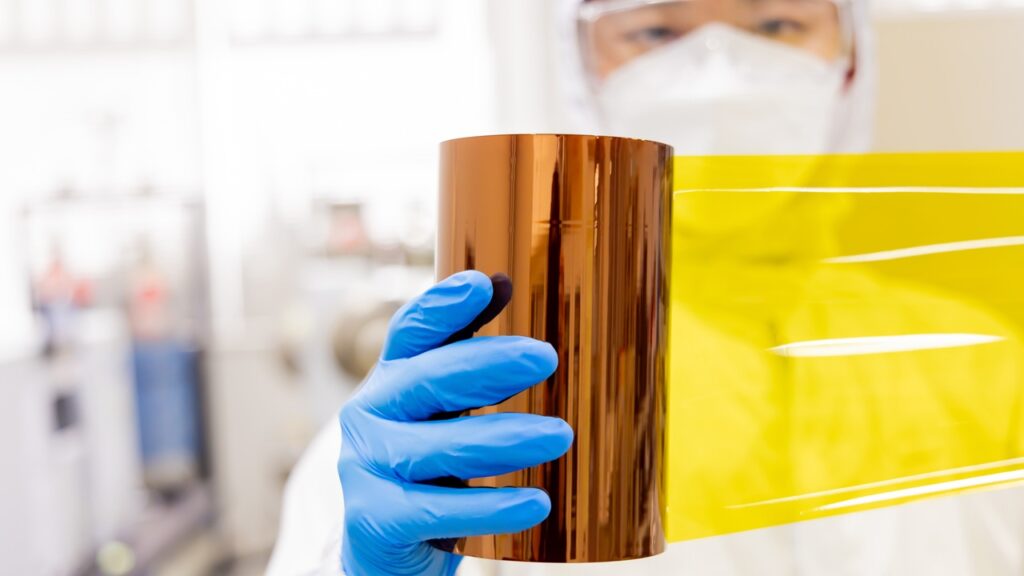

Smartphones, EV battery insulation materials, medical sensors, and more.

In today’s products, even a 0.01 mm deviation or burr can cause critical defects such as:

• Blurring

• Short circuits

• Measurement failures

Even when drawings specify ±0.05 mm or ±0.02 mm, we often hear from manufacturing sites:

“We assembled exactly according to the drawing, yet misalignment still occurred.”

OTIS’s Commitment to Achieving ±0.01 mm Precision

We maintain the following four precision foundations entirely in-house:

1) Ultra-Precision In-House Mold Manufacturing

• Integrated design, machining, polishing, and maintenance

• Stable, repeatable precision maintained over more than one million shots

2) In-House Development and Customization of Equipment

• Equipment modified or uniquely designed according to application

• Many cases include adding original mechanisms from scratch

3) Constant-Temperature Environment & Dedicated Inspection System

• Processing and inspection under strict temperature control to prevent dimensional fluctuation

• Inspection is positioned as a core part of the tolerance-engineering process

4) Design Capability (Design-Driven Reproducibility)

• Stable production even in high-mix, variable-volume manufacturing

• Advanced know-how to predict and counteract where and how deviations occur

The True Cause of Inaccuracy May Be “Following the Drawing Exactly”

Even when parts are manufactured strictly according to drawings, minute deviations inevitably occur due to:

• Material shrinkage

• Warping

• Adhesive flow

• Transportation impact

At OTIS, instead of blindly following drawings, we re-engineer the process itself, for example:

• Intentionally offsetting molds by 0.02 mm

• Changing lamination sequences

By doing so, we ensure overall dimensional stability across the entire process.

Case Study: Stable Mass Production of 10 Million Pieces/Month at 0.025 mm Tolerance

A request from a parts manufacturer:

“We need stable production of 10 million pieces per month with a tolerance range of 0.025 mm. Other suppliers declined.”

• During the initial prototype phase, slight warping and burrs occurred.

• We redesigned the mold with a distortion-absorbing structure and reviewed the lamination process.

• As a result, we achieved a 100% pass rate across all lots, and the product continues in mass production today.

Conclusion: Precision Is the Result of Design × Equipment × On-Site Expertise

Achieving ±0.01 mm is not possible with processing technology alone.

At OTIS, we sustain precision through total engineering capability, including:

• In-house mold design and fabrication

• Equipment customization and development

• Setup design and process analysis expertise

• Constant-temperature production environments and inspection design

For Those Facing High-Precision Manufacturing Challenges

• “We need to go below ±0.025 mm.”

• “Even when we follow the drawings, misalignment occurs.”

• “Precision can’t be maintained in mass production.”

• “We also need automation compatibility.”

Why not solve these challenges together with OTIS engineers?

Koji Kakumoto

OTIS Corporation

After studying abroad for language training and gaining experience in planning and product development at a trading company, I joined OTIS Corporation in 2011.

I have worked primarily in corporate planning while also being involved in manufacturing and engineering operations. Since 2018, I have served as President and CEO, focusing on driving business growth and strengthening the organization.

This article is intended for educational and informational purposes only and does not refer to or endorse any specific company, product, or proprietary technology.